Manufacturing Process

Premium quality begins with process control

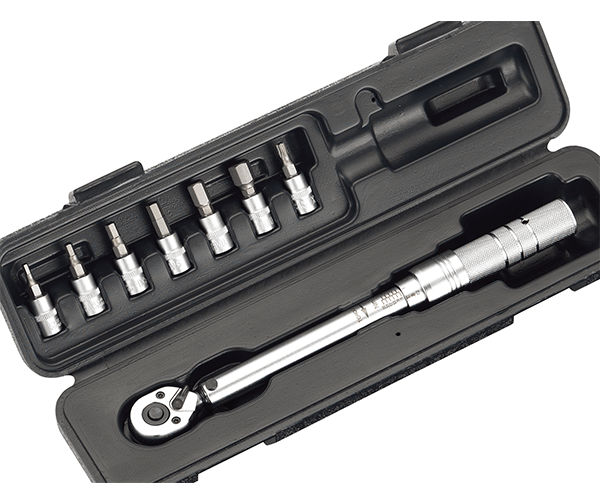

Torque-Tech manufacturing competence involves a large number of our own patents and constant refinements undertaken on our manual hand torque wrench products ensure a maximum performance standard.

The manufacturing management is extremely important for the quality products. Torque-Tech focuses not only Process Control、Assembly Service, but also Quality Assurance and Supply Chain Management.

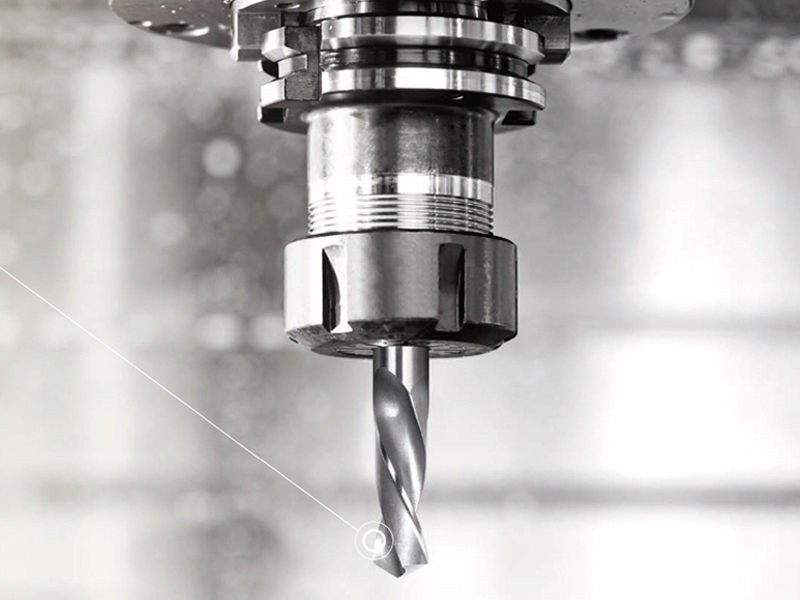

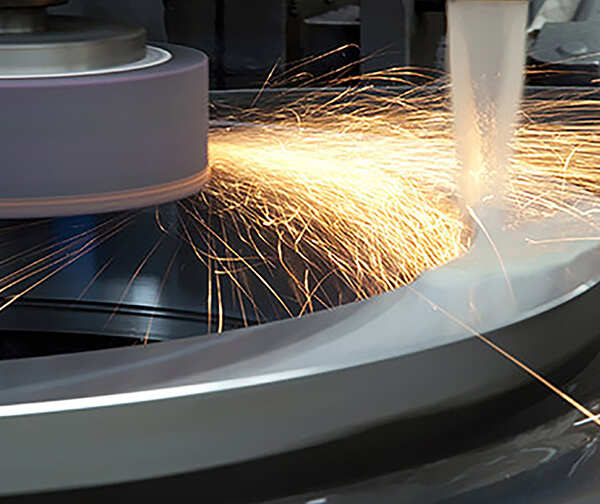

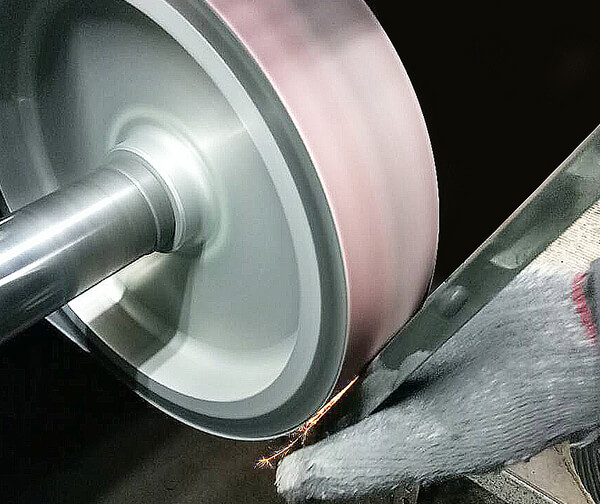

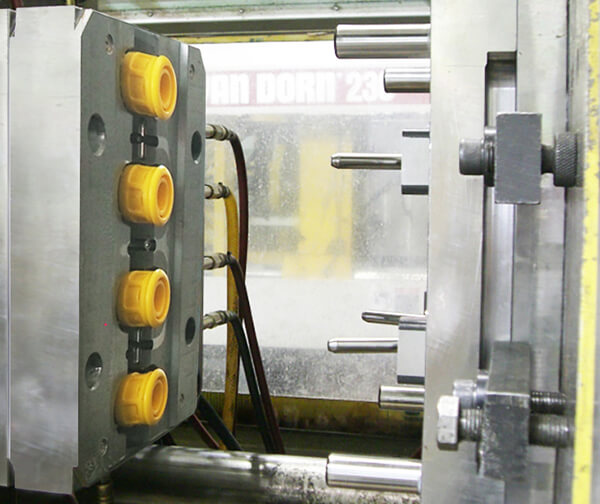

Especially, the production of consistent products contain from continuous process operation. It includes tube extrusion、grainding、milling、lathing、drilling、groving、heat-treament、polishing、sand blasting、electro-plating、laser、assembly、calibration、packaging to final quality inspection.

We truly believe premium quality is carrying out optimum material properties, ergonomic perfection as well as maximum safety and long life cycles. The torque tools we have made it possible for us to provide quality tools adapted to your various fields of applications. Should that not be sufficient in a particular instance, then we will construct a customized tool to solve your technical difficulty.

01Forging

02Surface Grinding

03Centerless Grinding

04CNC Milling

05CNC Lathing

06Grooving

07Drilling

08Knurling

09Heat treatment

10Polishing

11Vibration

12Sand blasting

13Plating

14Plastic Injection

15Insert Moulding

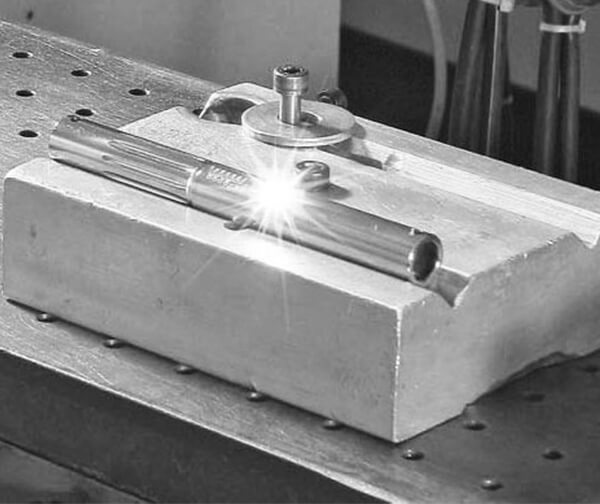

16Laser

17Assembly

18Calibration

19Packaging